Matters Need Attention For Floor Heating Installation?

But after you receive the product, you must first check the model, size, material brand, etc. of the product, and confirm that the manufacturer has sent the correct product as required, and construction can only be started after it is correct.

Then the following introduces the floor heating installation process steps and precautions.

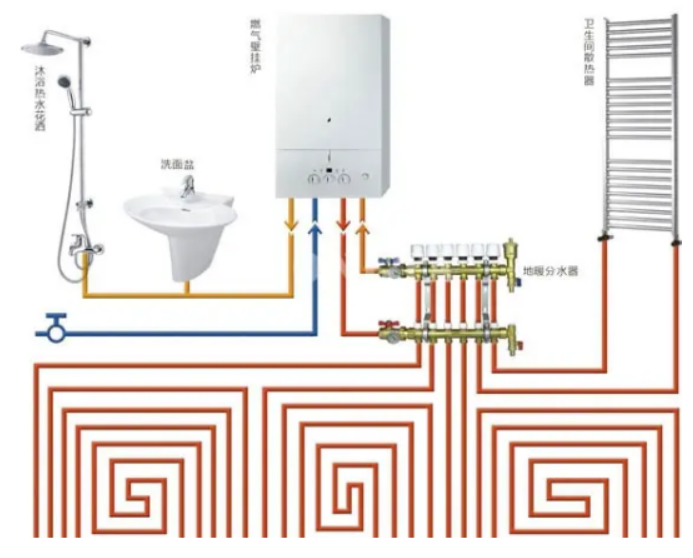

Installation of floor heating main pipeline

1) Pipe cutting: special pipe scissors should be used for pipe cutting, burrs and burrs should be removed from the cut section, and the sectional surface of the pipe must be perpendicular to the pipe axis.

2) Pipeline expansion: Qualified pipe protectors must be used, and pipe expansion must be carried out according to the standard process of pipe protection. After completion, carefully check that there is no damage to the expansion. If it is unqualified (uneven expansion, cracking, etc.), the connection is prohibited.

3) Compression connection: professional compression tools must be used, and the pipe fittings and pipes must be pressed in place to ensure that the loading port of the pipe is flush with the pipe fittings.

4) Preliminary requirements for piping in the heating machine room: reasonably arranged in combination with the actual situation on site. Pay attention to the embedded interface depth, height from the ground, interface spacing, and arrangement order.

This is our Facebook Website: www.facebook.com

Diversity tank installation

1) The height of the bottom of the diversion tank from the ground is 250m (original ground).

2) Back of the diversion water tank: more than 20mm of space should be reserved for the later wall treatment.

3) Reservation method for the front of the diversity water tank: A. If the wall is tiled, the tank body exceeds the wall by 20mm B. If the wall is painted, the tank body is flat on wall C. In other cases, negotiate and deal with it. For example, there is a wall panel on the wall For stone, coordinate pre-dimensions before installation.

4) The diversion tank must be secure. And filled with blowing agents all around, and remove the excess after the blowing agent has solidified.

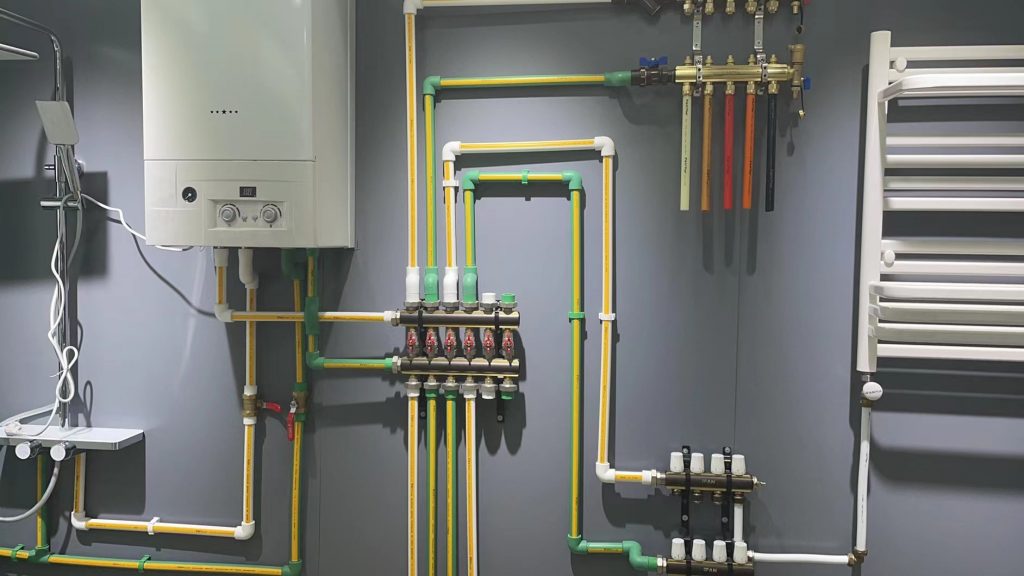

Manifold installation

1) the manifold is on the top. the sub-collector is on the bottom. And the installation is level (use a level).

2) The pipes entering and exiting the manifold from the ground needs to be fixed and protected with plastic elbow sleeves, and the exposed pipes must be kept warm.

3) The pipes in the box must be arranged neatly and orderly, and the connecting pipes must be firm and reliable. And the coil circuit must not be connected incorrectly.

4) After the installation is completed, the Manifold must be equipped with a dust cover to protect the finished product.

Floor heating electrical installation

1) The location of the floor heating thermostat and the direction of the line need to be planned first. and the owner should confirm it (a two-in-one thermostat for supply and use).

2) The electrical piping must be horizontal and vertical. And the bottom box of the thermostat must be flush with the bottom box of the switch panel.

3) The floor heating power supply is unified to take power from the main unit (wall-hung boiler). And the two power supplies are taken from the air-conditioning circuit.

4) Requirements for electrical installation in the diversion water tank: A. The electrical pipes are neatly arranged and of the same length (200mm in the tank). And are uniformly arranged on one side of the water diversion tank; B. The length of the wires is appropriate, and the wiring and binding are standard and beautiful; C. The corresponding room Electrical circuits must be clearly marked on the conduit.